Transonic Converging

/ Diverging Nozzle Tutorial

Figure 21

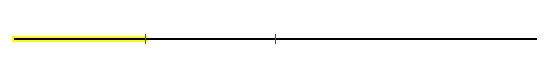

Figure 21. Transonic Nozzle Physical

Problem Definition

Figure 21 shows the nozzle geometry to be studied.

The domain of the nozzle runs from 0.0 to 1.0. The nozzle is

defined in three sections -- a straight section, a converging section, and

a diverging section. The respective area variations for these three

sections are given in Table 3.

Table 3. Area

Variation Polynomials by Zone for Transonic Nozzle

|

1

|

|

2

|

|

3

|

|

Inlet conditions are known completely in terms of Mach number, pressure,

and temperature. Two different cases will be studied with two different

outlet conditions. These boundaries will be discussed after creating

the geometry.

First, the physical domain needs to be divided to

reflect the three zones of the problem. This can be done by starting

Gryphon with a fresh physical model (the default when it starts up), and

switching to the model navigation tab (which is also the default). The

domain already runs from x=0.0 to x=1.0, so this can be left

alone. The default physical model initially starts with a single

segment within this domain. This can be changed by going to the Grid

< Add Segment Divider ... menu command at the top. In the simple

dialog that appears, enter a divider at x=0.25 and press "Apply" followed

by another divider at x=0.50 and press "OK". The tally in the

segment divider dialog should increase to 2 when the apply button is pressed.

After, the dialog clears, the GUI should update and the model should

look like the one shown in Fig. 22. This corresponds to the three

sections above in Fig. 21.

Figure 22

Figure 22. Physical Model Domain

for Nozzle

Next, the areas need to be defined as given in Table

3. This is done by opening the algebraic area rule dialog from the

Grid < Add Area Rule... command. The three area rules can

be added in any order by selecting the polynomial variation in this dialog

and entering the coefficients in front of each polynomial term. After

each, press "Add." Press "Done" when finished. The number of rules

defined should increase after each is added. The final area rule is

shown in Fig. 23 after the "Add" button has been pressed (the tally shows

3 rules already present).

Figure 23

Figure 23. Area Rule Addition Dialog

After closing the area rule dialog, the area rules must

be attached to the segments and the number of divisions set for each segment.

Back in the model navigation tab, the segments can be indexed through

using the segment number spinner on that navigation tab. The currently

selected segment is highlighted in the graph window in yellow. The

radio button should be selected for using an area rule (rather than an area

list) by default in each segment, so the one needs only to select the appropriate

area 1 - 3 for each. While doing this, set the number of divisions

to 12 for segment 1, 24 for segment 2, and 75 for segment three, with spacing

ratios of 1.02 left-to-right, 1.065 right-to-left, and 1.01 left-to-right

for segments 1 to 3 respectively. These values are summarized in Table

4.

Table 4. Grid

Related Parameters for Transonic Nozzle Cases

|

segment #

|

area rule

|

divisions

|

spacing

|

space orientation

|

1

|

1

|

12

|

1.020

|

left-to-right

|

2

|

2

|

24

|

1.065

|

right-to-left

|

3

|

3

|

75

|

1.010

|

left-to-right

|

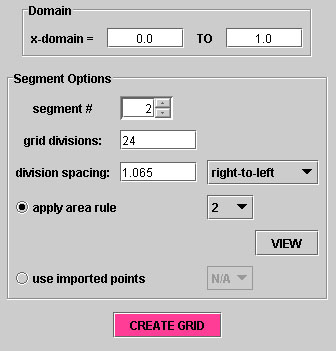

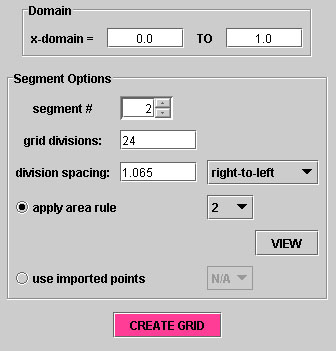

Figure 24 shows what the model navigation bar should look like for the

second segment as an example.

Figure 24

Figure 24. Model Navigation Tab Showing

Segment #2 Parameters

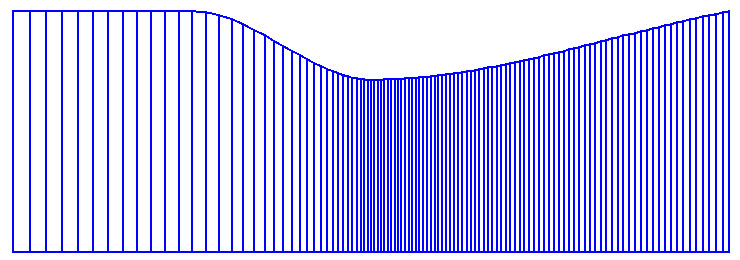

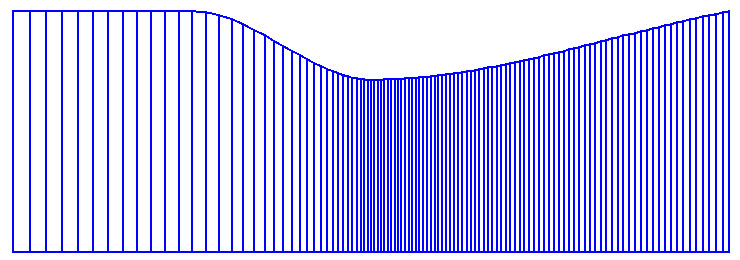

After setting this up, press "Create Grid" and the grid

should be automatically generated. This result is shown in Fig. 25.

Figure 25

Figure 25. Transonic Nozzle Grid

Now is a good time to save the model information. If

the program is not being run as an applet in protected mode, one may go

to the file menu and select File < Save.... This will bring

up a dialog, and a suitable name can be entered. Enter something like

"nozzle" in the space provided. Gryphon automatically appends a ".egd"

extension to the database.

Next, move to the BC navigation tab, and enter the boundary

condition information. The inlet should be applied at the left boundary.

Gryphon should have defaulted to an inlet condition here already.

Since the inlet boundary is to be a steady (constant) boundary, the

inlet conditions can be set by pressing the "modify" button. Select

"pressure, temperature" from the property selection box, and enter inlet

conditions of 250,000 for pressure and 350 for temperature. Select

"Mach" and enter 0.450 for a Mach number. The dialog may then be closed

by pressing the "OK" button.

Case #1: Extrapolated Nozzle

Two separate outlet boundaries will be studied. The

first case is for a constant extrapolation boundary on the outlet. This

is Gryphon's default for the right boundary, so this information may be

left alone. For initial conditions, the default of initializing via

the left boundary is a good choice for this problem.

The solution options for this problem may be set in

the solution navigation tab. The summary of the options is shown in

Fig. 26, which shows the solution tab as it should be configured.

Figure 26

Figure 26. Solution Navigation Tab

The problem is steady-state, and the number of iterations should be set

to 5,000. This is sufficient to fully converge this case, a fact which

shall be shown to be true shortly. The Euler Implicit scheme should

be selected as the time integration scheme. Set the CFL condition

to a localized limit, and enter a value of 1.0. This is a higher value

than can be used for an explicit scheme, but this value is a good choice

for implicit methods. The default of 3rd order is fine for the MUSCL

interpolation technique, but the limiter shoudl be changed to the van Albada

limiter. The limiter should not be particularly active for this case

since its solution will involve no shocks, but the min-mod limiter can affect

convergence during the transient start-up of the problem. Select the

Roe scheme as the flux scheme to be used since it offers the greatest accuracy.

Pressing the "SOLVE" button starts the solution. Gryphon

will show the solver dialog listing the progress in the solution. The

entire 5,000 iterations should typically take on the order of 1 - 2 minutes

to complete, but may vary significantly depending on the processor architecture

and operating system available. During this solution process, the

graphing window will show a real-time progress of the residual levels. The

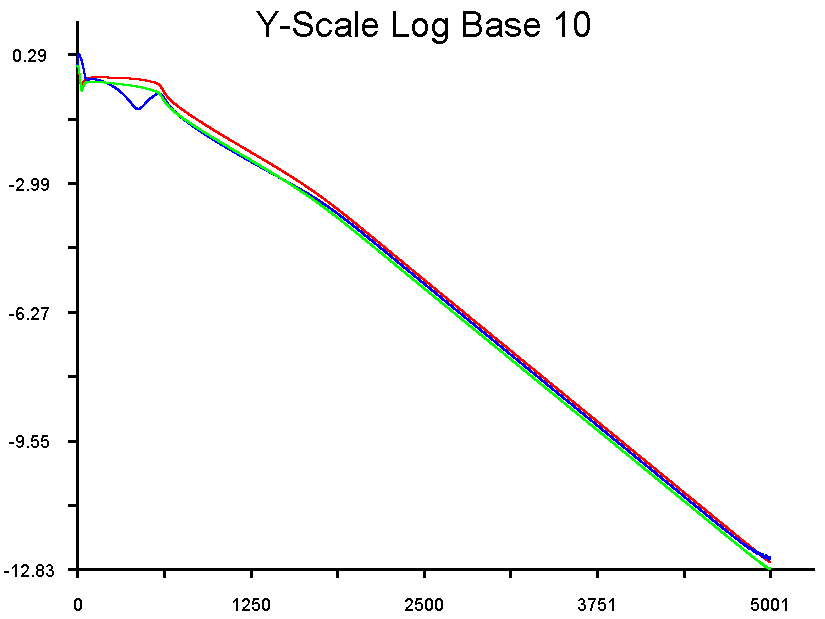

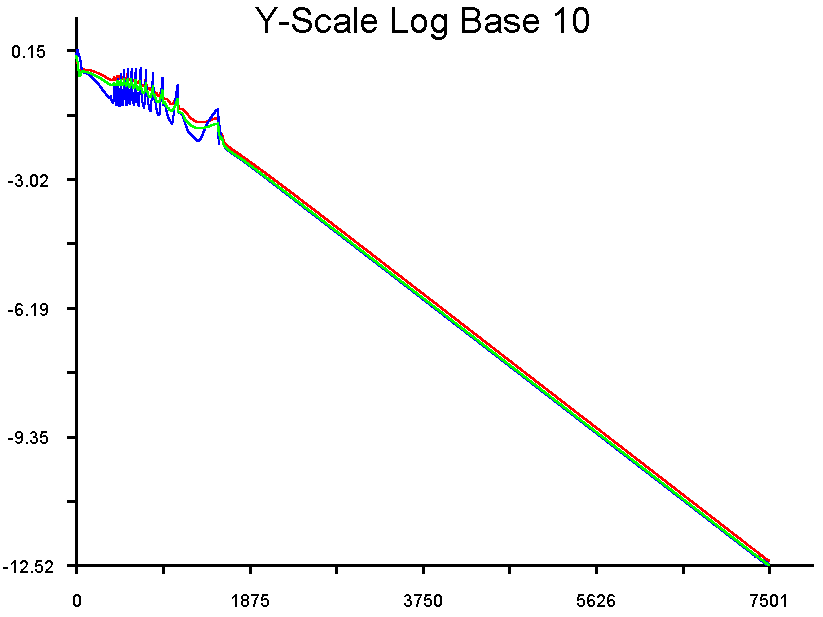

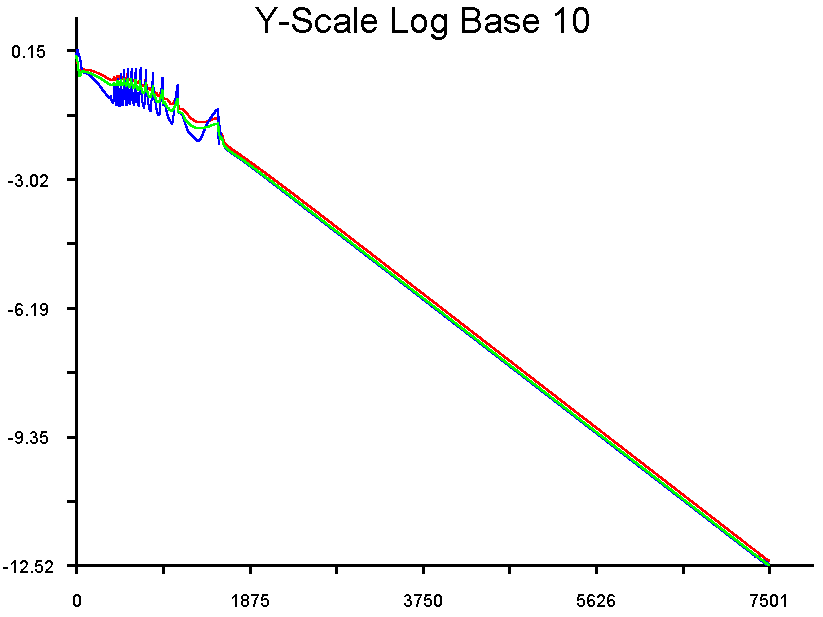

result of this residual monitoring is shown in Fig. 27.

Figure 27. Residual

History for Case #1: Outlet Extrapolation

This is the indication that excellent convergence is achieved by the end

of 5,000 iterations. The residual levels have dropped approximately

12 orders of magnitude and are close to machine zero.

With the solution available, it is again a good time

to save the newly generated data. Selecting File < Save...

from the main menu will do this. The solution data is included in the

latest save. It is then possible to look at the solution by going to

the Graph navigation tab. Here, select at the top in the line graph

panel to "plot versus x" by selecting the proper radio button. From

the line labeled "1st," select Mach number from the pull-down menu. Then,

at the bottom under the Contour Graph Options panel, choose to plot the first

item above by selecting the radio button labeled so. It is also helpful

to uncheck the box labeled for the grid lines. Press the "Update Graph"

button, and the graph of Mach number should be shown in the upper window

and the Mach number distribution should be shaded on the geometry in the

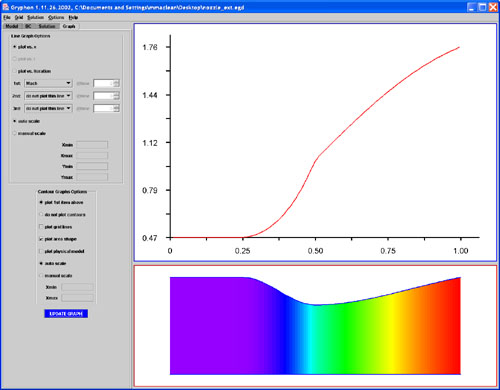

lower window. This scene is shown in Fig. 28.

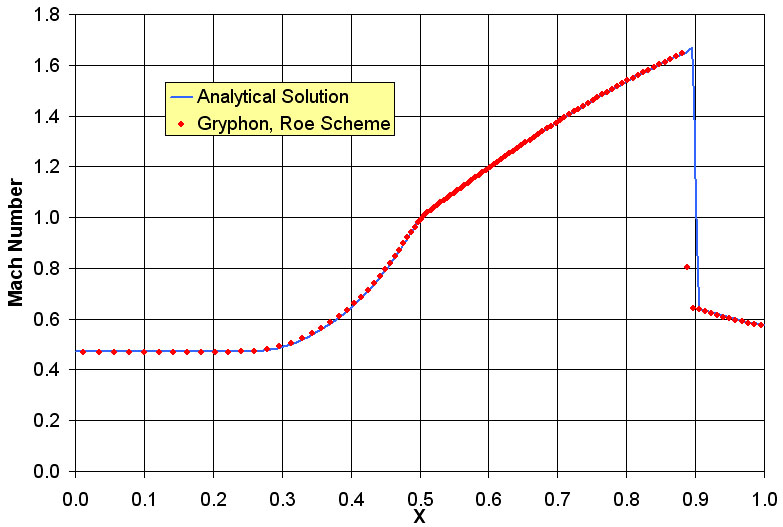

This solution can be compared with the expected solution

for validation purposes. From Anderson [1993],

the solution for a shockless nozzle with a supersonic outlet condition can

easily be found using the principles of inviscid quasi 1-D flow. The

prediction is accurate almost to the point of perfection throughout the

domain. The comparison between the analytical prediction and the Gryphon

solution is shown for the Mach number in Fig. 29. Also, it is worthwhile

to notice that the Mach number does indeed equal 1.0 at the throat as it

should.

Figure 29. Mach Number

Comparison between Analytical and Gryphon Solutions for Case #1: Outlet

Extrapolation

Case #2: Nozzle with Back Pressure

The second case which will be studied is that of a nozzle

with a known back pressure.This case is different and more complex than

the first case in that a subsonic outflow will be created by selection of

the back pressure strength and a shock will form in the nozzle. The

back pressure can be set by going back to the BC navigation tab. Here,

change the right boundary selection to "back pressure / subsonic out." Then,

press the "modify" button for this boundary and enter a value of 200,000

in the text box provided. This sets a back pressure of 80% of the inlet

total pressure.

The solution needs to be reset to run this case properly.

This also affords the opportunity to test a few of Gryphons other

features. By opening up the Solution menu, and selecting the Solution

< Reset Solution command. Gryphon will display a warning message

saying that the solution data will be deleted. This is fine. Then,

re-initialize the data by selecting the Solution < Initialize Grid

command. Since the initial conditions are specified to come from the

left inlet boundary, the entire flowfield should now be set to the subsonic

inlet conditions.

Since this problem is slightly more complex, a similar

level of convergence to case #1 requires that 7,500 iterations be used,

so the iterations should be changed to this on the Solution navigation panel.

Before solving, it is wise to save the model again, so this time,

select File < Save As... from the file menu at the top and enter

a new name for the model to avoid overwriting the other case. A name

like "nozzle_shock" is fitting, and Gryphon will again append the proper

extension to the name. Once saved, the solution can be generated by

pressing the "SOLVE" button. The residual history is similar to the

first case. It looks like that shown in Fig. 30.

Figure 30

Figure 30. Residual History for Case

#2: Specified Back Pressure

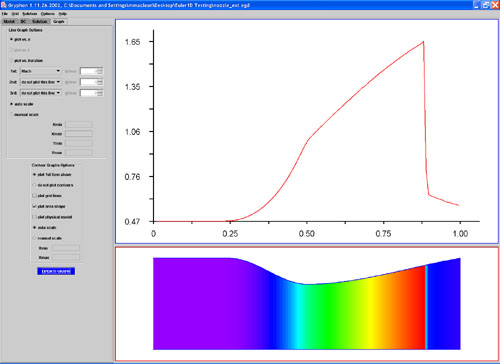

The resulting Mach number distribution for this case is shown in Fig. 31.

This plot is produced by following the instruction given at the end

of the first case above.

Finally, Fig. 32 shows a comparison of Mach number and pressure distribution

with analytical prediction methods for this case. For an analytical

prediction, invscid equations had to be connected to the analytical equations

for a normal shock. This requires an iterative process to properly locate

the shock. As such, the analytical solution is also somewhat approximate.

However, the agreement between the two solutions is evident.

(a) Mach Number Comparison

(b) Pressure Comparison

Figure 31. Comparison between Analytical

and Gryphon Solutions for Case #2: Specified Back Pressure

One should notice in particular that the pressure does actually go to 200,000

at the outlet as the boundary condition specified.

<previous:

|

up to Tutorials

|

next: Shocktube Tutorial >

|